Heat Treatment of 7075 Aluminum Plate

Heat treatment is a critical process in the manufacturing of aluminum plates. In this article, we will explore the heat treatment techniques used for 7075 aluminum plates, a high-strength alloy widely used in various industries. Understanding the heat treatment process for 7075 aluminum plates is essential for optimizing their mechanical properties and ensuring their suitability for specific applications.

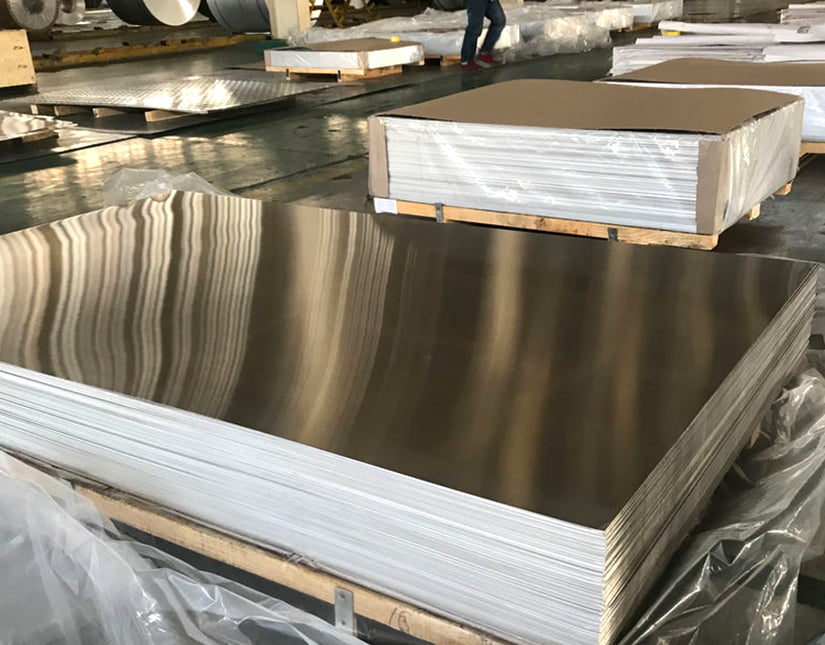

What is 7075 Aluminum Plate?

7075 aluminum is an alloy composed primarily of aluminum, zinc, and small amounts of copper, magnesium, and chromium. It is renowned for its exceptional strength-to-weight ratio and high tensile strength. These properties make 7075 aluminum plate a popular choice in industries such as aerospace, automotive, and marine, where lightweight materials with excellent mechanical properties are required.

Heat Treatment Techniques:

- Solution Heat Treatment:

The first step in the heat treatment process of 7075 aluminum plates is the solution heat treatment. The purpose of this treatment is to dissolve the alloying elements uniformly within the aluminum matrix. The plates are heated to a specific temperature and held for a specified duration to achieve a solid solution. This process eliminates any residual stresses and enhances the material’s formability. - Quenching:

Following the solution heat treatment, the plates are rapidly quenched in water or other quenching media to achieve maximum strength. Quenching prevents the formation of undesirable precipitates and ensures a fine-grained microstructure, contributing to the improved mechanical properties of the aluminum plates. - Aging:

The aging process further enhances the strength and hardness of the 7075 aluminum plates. It involves heating the quenched plates to a lower temperature and holding them for a specific period. This allows the alloying elements to precipitate, forming fine particles that strengthen the material. The two common aging methods for 7075 aluminum plates are natural aging and artificial aging.

- Natural Aging: This method involves exposing the plates to room temperature for an extended period. Natural aging is a slow process but can be advantageous for certain applications where time is not a critical factor.

- Artificial Aging: In artificial aging, the plates are heated to a higher temperature than during natural aging. This accelerates the precipitation process, reducing the aging time significantly. Precise control of temperature and time is crucial to achieve the desired mechanical properties.

Benefits of Heat Treatment:

Proper heat treatment of 7075 aluminum plates offers several benefits:

- Increased Strength: Heat treatment enhances the strength of the plates, making them suitable for demanding applications that require high tensile strength and durability.

- Improved Hardness: The aging process increases the hardness of the plates, improving their resistance to wear and deformation.

- Enhanced Formability: Solution heat treatment improves the formability of the plates, allowing for easier shaping and fabrication processes.

- Superior Corrosion Resistance: The heat treatment process optimizes the microstructure of the aluminum, leading to improved corrosion resistance, crucial for applications in harsh environments.

The heat treatment of 7075 aluminum plates is a crucial step in optimizing their mechanical properties. By employing proper solution heat treatment, quenching, and aging techniques, the plates can achieve enhanced strength, hardness, and corrosion resistance. As a leading manufacturer of aluminum products, Henan Worthwill Industry Co., Ltd. is committed to delivering high-quality 7075 aluminum plates that undergo meticulous heat treatment processes. Contact us to learn more about our range of aluminum products and their exceptional performance in various industries.