Exploring Aluminum Plate Finishes for Diverse Applications

As a leading player in the aluminum industry, Henan Worthwill Industry Co., Ltd. takes pride in offering a comprehensive range of high-quality Aluminum Plate products. In this article, we will delve into the world of “Aluminum Plate Finishes,” exploring the various surface treatments and coatings available to meet the diverse needs of our customers.

Understanding the Importance of Surface Finishes:

The surface finish of aluminum plates plays a crucial role in both aesthetics and functionality. It not only enhances the visual appeal of the product but also provides essential characteristics such as corrosion resistance, durability, and ease of maintenance.

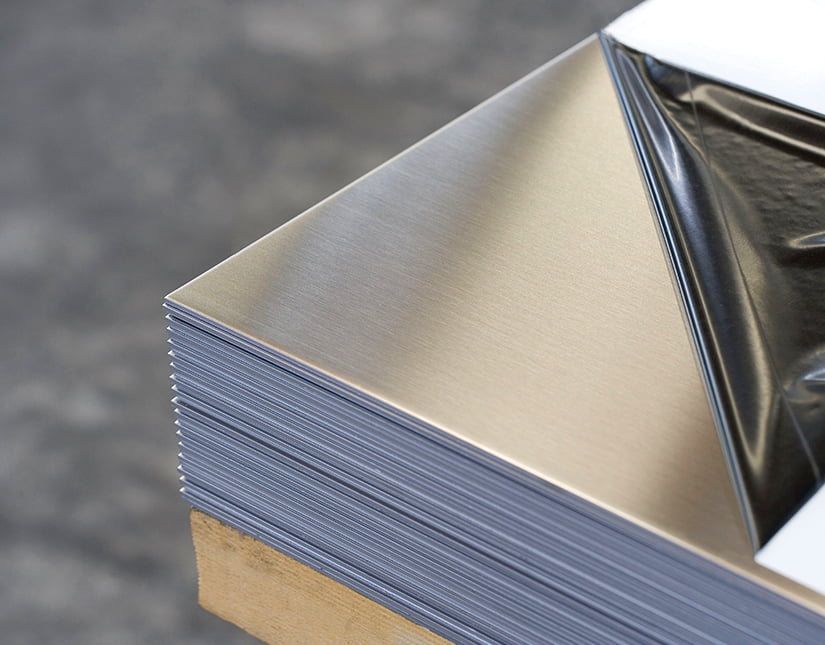

- Mill Finish: The most basic form of aluminum plate finish is the mill finish, which involves the metal being as it exits the rolling mill. While mill finish provides a natural and clean appearance, it lacks additional protective coatings. This finish is an excellent choice for applications where aesthetics are not a primary concern.

- Anodized Finishes: For enhanced corrosion resistance and improved durability, anodizing is a popular choice. This electrochemical process creates a protective oxide layer on the surface of the aluminum, offering a range of colors and finishes. Anodized aluminum plates are ideal for architectural applications, providing both functionality and aesthetic appeal.

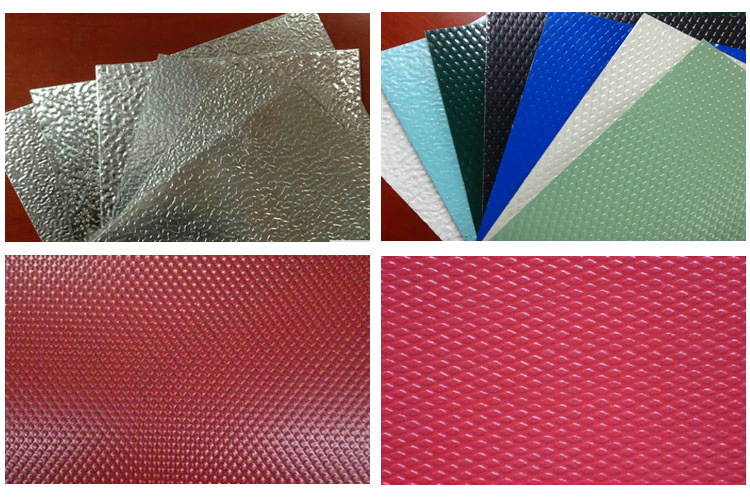

- Powder Coating: Powder coating is another widely used method for aluminum plate finishes. It involves applying a dry powder to the surface, which is then cured under heat. This process results in a durable and uniform coating that is resistant to chipping, fading, and scratching. Powder-coated aluminum plates are suitable for various industries, including automotive and industrial applications.

- Polished Finishes: For a high-gloss and reflective surface, polishing is an excellent option. This finish not only enhances the appearance of aluminum plates but also improves their corrosion resistance. Polished aluminum plates are often chosen for decorative applications, such as architectural elements and interior design.

- Painted Finishes: Painting aluminum plates allows for endless possibilities in terms of color and design. The addition of a protective paint layer not only enhances aesthetics but also provides an extra layer of defense against environmental elements. This finish is customizable to match specific project requirements.

Henan Worthwill Industry Co., Ltd., as a renowned Aluminum Plate Manufacturer and Factory, understands the importance of offering diverse surface finishes to cater to the unique needs of our customers. Whether you are looking for a simple mill finish or a more complex anodized or powder-coated solution, our range of aluminum plates finishes ensures that you find the perfect match for your application. Contact us today to explore our comprehensive selection of high-quality aluminum products that combine functionality with aesthetic appeal.