Applications of 6061 Aluminum Plate in the Mold Manufacturing Industry

In the mold manufacturing industry, the choice of materials plays a vital role in ensuring high-quality and efficient production processes. One such material that has gained significant popularity is the 6061 aluminum plate. Renowned for its exceptional properties, the 6061 aluminum plate offers numerous advantages, making it a preferred choice for various mold applications. In this article, we will explore the applications of 6061 aluminum plate in the mold manufacturing industry and highlight its key benefits.

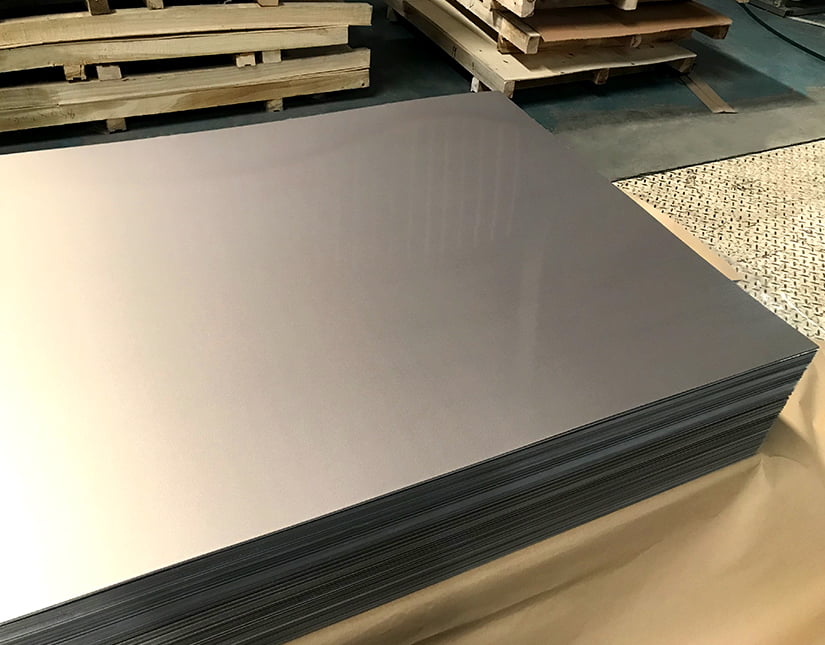

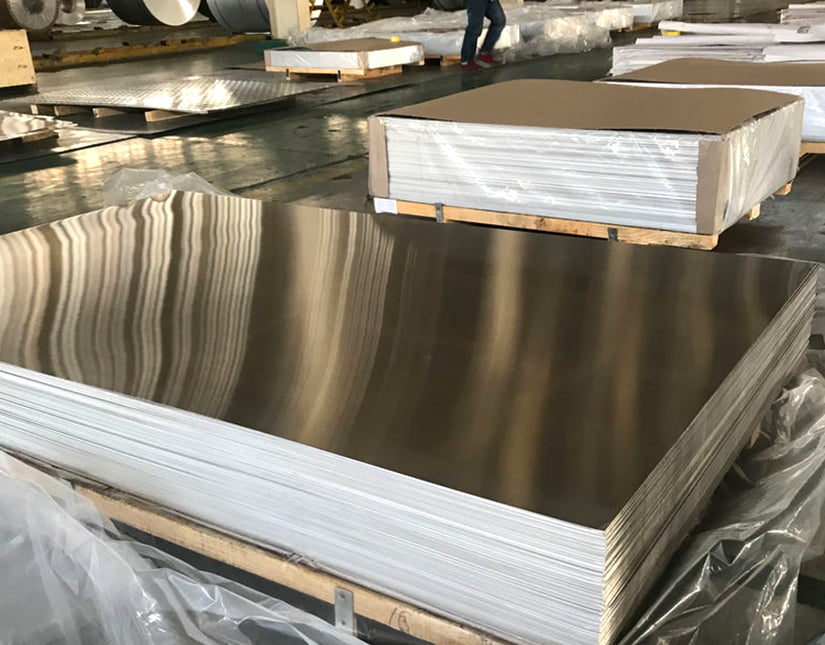

Overview of 6061 Aluminum Plate

The 6061 aluminum plate belongs to the 6xxx series of aluminum alloys, which are known for their excellent strength-to-weight ratio and corrosion resistance. This alloy is composed primarily of aluminum, magnesium, and silicon, resulting in a material that offers exceptional mechanical properties, weldability, and machinability. These characteristics make it highly suitable for mold manufacturing applications.

Applications of 6061 Aluminum Plate in the Mold Manufacturing Industry

- Injection Molds

6061 aluminum plates are widely used in the production of injection molds. The excellent machinability of this alloy allows for intricate mold designs, ensuring precise and accurate manufacturing of plastic components. The high strength and durability of 6061 aluminum enable it to withstand the high pressures and temperatures involved in the injection molding process, resulting in prolonged mold life and consistent production quality. - Blow Molds

Blow molding is another common process employed in the manufacturing of plastic products.6061 aluminum plates are utilized in the production of blow molds due to their excellent thermal conductivity. The efficient heat transfer properties of this alloy enable rapid cooling of the molds, reducing cycle times and improving overall production efficiency. - Rotational Molds

Rotational molding is a technique used for producing hollow plastic parts. 6061 aluminum plates find application in rotational molds due to their high strength and resistance to deformation under heat. These molds can withstand the rotational forces and elevated temperatures required for the molding process, resulting in the production of high-quality, uniform plastic components.

Key Benefits of Using 6061 Aluminum Plate

- Lightweight and Durable

6061 aluminum plate exhibits a high strength-to-weight ratio, making it a lightweight yet robust material for mold manufacturing. Its durability ensures prolonged mold life and reduces the need for frequent replacements, contributing to cost savings. - Excellent Machinability

The 6061 aluminum plate is highly machinable, allowing for complex mold designs and precise manufacturing. This property enables the production of molds with intricate features and tight tolerances. - Corrosion Resistance

The corrosion-resistant nature of 6061 aluminum plate ensures the longevity of molds even in demanding operating conditions. It offers protection against rust and other forms of corrosion, maintaining the mold’s performance and extending its service life.

The 6061 aluminum plate is a highly versatile material that finds extensive application in the mold manufacturing industry. Its superior properties, including lightweight construction, excellent machinability, and corrosion resistance, make it an ideal choice for injection molds, blow molds, and rotational molds. By utilizing 6061 aluminum plate in mold production, companies can expect enhanced productivity, improved quality, and cost-effective operations. Contact Henan Worthwill Industry Co., Ltd., to explore the wide range of 6061 aluminum plate products suitable for mold manufacturing.