Surface Finishing Options for 7075 Aluminum Plate

Welcome to Henan Worthwill Industry Co., Ltd., a leading manufacturer of aluminum products. In this article, we will explore the various surface finishing options available for 7075 aluminum plate. By leveraging these options, you can enhance the aesthetics and performance of your products, making them stand out in the market. Read on to discover the different surface finishing techniques and their benefits.

1.Anodizing:

Anodizing is a popular surface finishing technique for aluminum that offers numerous advantages. It involves creating a protective oxide layer on the aluminum surface through an electrochemical process. Anodizing provides excellent corrosion resistance, improves wear resistance, and enhances the durability of the 7075 aluminum plate. Additionally, it allows for a wide range of color options, making your products visually appealing.

2.Powder Coating:

Powder coating is another widely used surface finishing method for aluminum. In this process, a dry powder is electrostatically applied to the 7075 aluminum plate and then cured to form a durable, attractive coating. Powder coating provides excellent resistance to impact, chemicals, and UV rays. It offers a broad spectrum of colors and finishes, allowing you to achieve the desired appearance for your products while providing enhanced protection against wear and corrosion.

3.Brushed Finish:

A brushed finish involves the use of abrasive materials to create a textured pattern on the surface of the 7075 aluminum plate. This technique provides a unique, aesthetic appeal by producing parallel lines or swirls. Brushed finishes are often used in architectural applications, where visual appeal and a modern look are desired. The brushed finish also helps to hide scratches and fingerprints, making it suitable for products that require frequent handling.

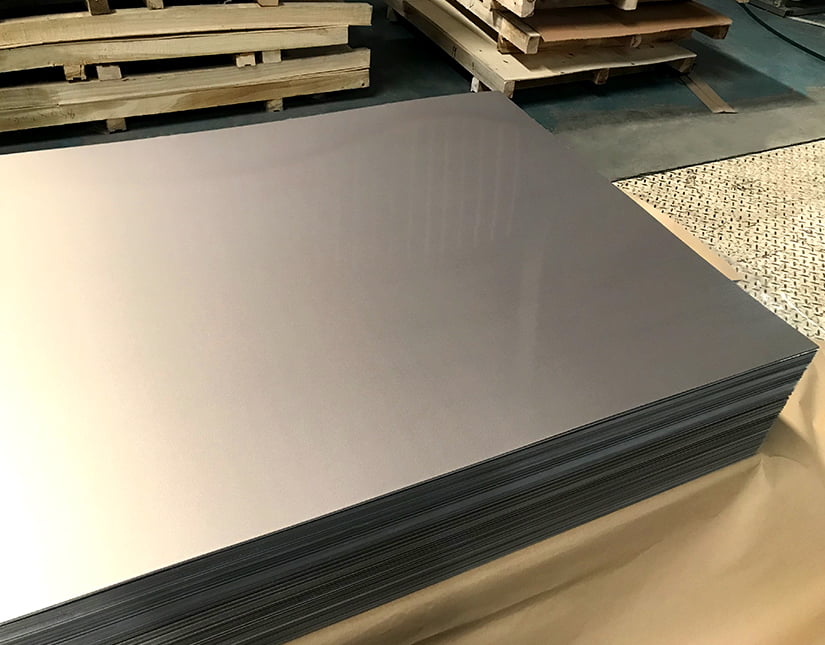

4.Polishing:

Polishing is a surface finishing option that involves mechanically smoothing the surface of the 7075 aluminum plate to achieve a reflective, mirror-like finish. This technique enhances the visual appeal of your products, giving them a high-end appearance. Polished aluminum surfaces are easy to clean and maintain and can create a sense of luxury and sophistication.

5.Textured Finish:

For applications that require enhanced grip or a unique appearance, textured finishes are an excellent choice. Texturing can be achieved through various methods like embossing, etching, or engraving. These finishes provide improved tactile properties and can be customized to suit your specific design requirements. Textured finishes not only enhance aesthetics but also offer practical benefits such as slip resistance in certain applications.

Choosing the right surface finishing option for your 7075 aluminum plate is crucial to ensure the visual appeal, durability, and performance of your products. Anodizing, powder coating, brushed finishes, polishing, and textured finishes are all effective methods to achieve your desired results. At Henan Worthwill Industry Co., Ltd., we offer a wide range of surface finishing options to meet your specific needs. Contact us today to learn more about how our surface finishing services can elevate your products to new heights.