Welding Techniques for 5052 Aluminum Plate

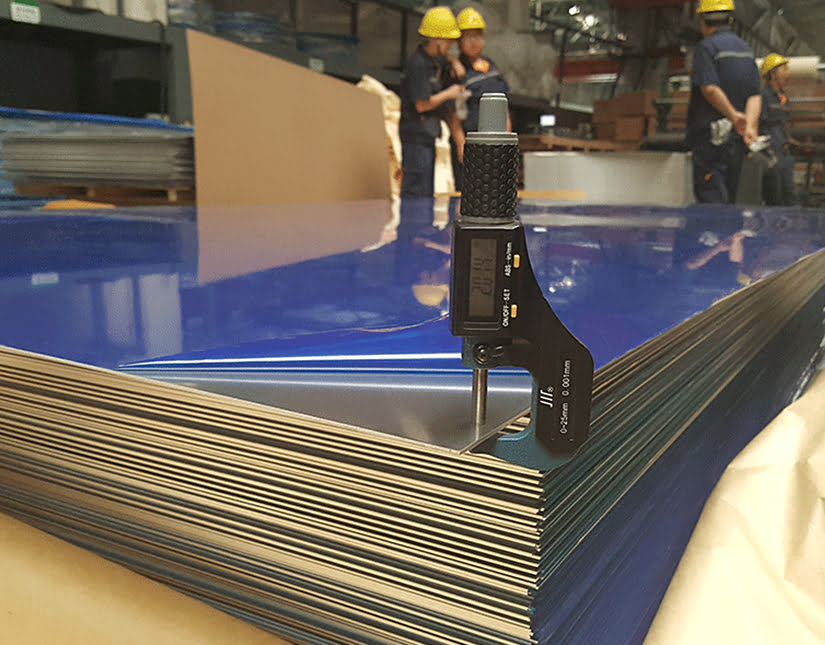

Henan Worthwill Industry Co., Ltd., a leading aluminum products manufacturing company, is dedicated to providing high-quality aluminum plates for various applications. In this article, we will discuss welding techniques for 5052 aluminum plate, a popular choice known for its excellent corrosion resistance, weldability, and formability. Understanding the proper welding techniques is crucial to ensure strong and reliable weld joints in 5052 aluminum plate applications.

1.Gas Metal Arc Welding (GMAW):

Gas Metal Arc Welding, also known as MIG (Metal Inert Gas) welding, is a widely used welding technique for 5052 aluminum plate. It involves creating an electric arc between a consumable electrode and the workpiece, while a shielding gas protects the weld area from atmospheric contamination. GMAW offers high welding speed and good weld quality, making it suitable for various applications such as automotive components and structural fabrications.

2.Gas Tungsten Arc Welding (GTAW):

Gas Tungsten Arc Welding, commonly referred to as TIG (Tungsten Inert Gas) welding, is another popular technique for welding 5052 aluminum plate. GTAW utilizes a non-consumable tungsten electrode and a shielding gas, typically argon, to protect the weld area. This technique provides precise control over the welding process, resulting in high-quality welds with excellent aesthetics. GTAW is often used for applications that require exceptional weld quality, such as aerospace components and marine structures.

3.Friction Stir Welding (FSW):

Friction Stir Welding is a solid-state welding technique that offers several advantages for joining 5052 aluminum plate. It involves a rotating tool that generates heat and mechanical agitation to create a solid-state bond between the plates. FSW produces welds with excellent mechanical properties, low distortion, and high productivity. This technique is commonly used in the transportation industry for applications like shipbuilding, rail cars, and automotive structures.

4.Laser Beam Welding (LBW):

Laser Beam Welding is a precise and efficient welding technique suitable for 5052 aluminum plate. It utilizes a highly concentrated laser beam to melt and join the workpieces. LBW offers narrow weld profiles, minimal heat-affected zones, and high welding speeds. This technique is often employed in industries where precision and minimal distortion are crucial, such as electronics, aerospace, and medical equipment manufacturing.

Proper welding techniques are essential for achieving strong and reliable weld joints in 5052 aluminum plate applications. Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), Friction Stir Welding (FSW), and Laser Beam Welding (LBW) are among the commonly used techniques. Each technique has its advantages and is suitable for specific applications. At Henan Worthwill Industry Co., Ltd., we ensure that our 5052 aluminum plate is designed with excellent weldability, allowing for successful welding using these techniques. For more information on our products and services, please visit our website or contact us directly.